You don’t have to be interested in photography for very long to figure out gear, especially quality gear, that doesn’t come cheap.

While it’s easy to understand why our high tech camera bodies are costly, you may find yourself wondering why camera lenses are so expensive? They may seem like rather simple devices, that funnel light into the camera that does all of the work. However, the road from idea to finished product is quite the journey.

In this article, we are going to look at the

reasons behind the expensive price tag most lenses have, and also look at how

lenses are made in the first place.

Why Camera Lenses Are So Expensive?

1. Complexity of Design

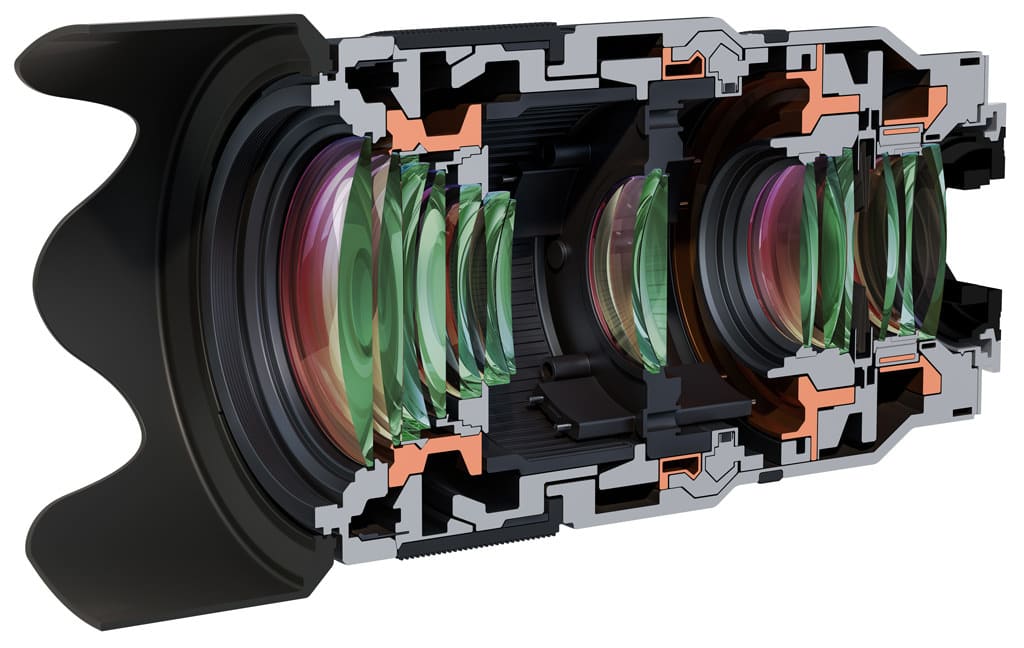

While a camera lens might seem like a simple concept, the design of each can be highly sophisticated. This complexity is in part due to the job lenses perform.

See also: Best Lens for Bird Photography

A camera lens’s main job is to focus and manipulate the light as it passes through the camera and onto the sensor. It accomplishes this by bending and filtering the light using numerous elements within the lens body. The shape, thickness, clarity, curvature, and position of these elements must be calculated very precisely.

Related: How to Choose a Camera Lens

The lens must also be lightweight and small

enough to be usable when mounted on a camera. Being able to fit the necessary

components into the lens body further complicates the design process.

An additional aspect of the design that can often be overlooked is the weather sealing. The seals and coatings on new lenses are what allows them to be used outside of a studio. They prevent water, dirt, and dust from getting inside of the lens body.

2. Research & Development

Another factor that contributes to the cost of high-quality optics is the research and development, often referred to as R&D, that companies put into their products. This research can involve not only how to make a new lens, but also what materials to use.

Related: How to Choose the Best Lens for Astrophotography

R&D departments are also charged with

figuring out what to make. Studying new trends in photography and understanding

the market they are developing lenses for is an essential step. These studies

often involve extensive polling and market research that is both time-consuming

and labor-intensive.

High quality Fujifilm zoom lens

Within the highly competitive world of

photography, it is also vital that companies stay on the leading edge of both

technology and new materials. This approach helps the company ensure that’s its

loyal customers don’t get tempted to switch providers looking for greener

pastures in new offerings. Of course, this research also adds cost to any final

product that goes to market.

3. High-Quality Raw Materials

When manufacturing lenses, it is essential for the company to use high-quality materials, to ensure the lens functions as desired, consistently, and for a long time. One of the areas where this is most important is with the lens elements.

Related: Best Camera Lens Cleaning Kit

To function correctly, these elements must be

manufactured from extremely high-quality glass and calibrated to very exact

standards. The glass that is needed can be costly due to the high level of

refinement required, which adds to the cost.

The motors that drive the focusing are another

component that must be excellent quality. The motor needs to be fast, quiet,

and reliable. It also needs to be small and lightweight. This adds

significantly to the overall price and to the manufacturing costs.

4. Precision Manufacturing

Once you have all the necessary components and suitable design, you have to build the lens itself. Packing all of these high-quality and precise components into a small package with precise tolerances is not an easy job. The tight calibrations and exact positioning needed requires highly skilled workers and precision machinery.

Another factor with manufacturing lenses is that it requires a lot of hands-on manual labor. This means more skilled laborers and less machine automation, which drives up costs. Without being able to use robotic automation, the speed of manufacture is also significantly lower than other types of equipment.

Related: What Is Chromatic Aberration? How to Avoid or Fix It

Lenses also have to be manufactured in an

incredibly and nearly sterile environment in order to prevent dust, dirt, and

moisture from getting into the camera body before it is sealed. These types of

environments require many additional processes and procedures that both add to

cost and reduce the speed of production.

5. Quality Control

After the manufacturing of the lens is

complete, it is time to move on to quality control. Photographers require

absolute perfection with the lenses. When you combine this with the already

complicated manufacturing process and intricate design, you have a high probability

of a newly manufactured lens not making the cut.

$25,000 Sigma telephoto zoom lens

To make sure they are perfect, each lens must be inspected by quality control departments and certified ready to use. This inspection is often performed by hand with machinery that allows them to measure and test the lens.

Conclusion

When you look at all of the steps that go into researching, designing, and manufacturing a new lens, it starts to become more apparent why they are such expensive pieces of equipment. Fortunately for us photographers, most quality lenses are indeed an investment that will work for many years to come. This durability is due in part to the rigorous manufacturing process and quality standards that drive up the costs in the first place.

Related: Best Lenses for Nikon D3300

Because of this, a lot of photographers buy

their lenses pre-owned. If going through a camera shop or company that inspects

and cleans the lenses beforehand, pre-owned lenses will provide years of use

with no discernible difference from its new counterpart.

So the next time you are looking at new lenses

and see that huge price tag, remember what all was involved in getting that

lens ready to go. It might help a little with the sticker shock.